Meet Dr. Amy Elliott

3D Printing Scientist

Dr. Amy Elliott is a 3D printing scientist at Oak Ridge National Laboratory where she consults with manufacturers all across the US to ensure proper application of 3D printing technologies. Her research focuses on inkjet-based metal and ceramic 3D printing, in which she holds several patents. Outside of the lab, Amy spends time creating personal 3D printing projects and starring as a science personality to make STEM easier to understand and more accessible to the younger generation.

STEM to the Sky

Aug 1, 2023

- How did you first become interested in STEM?

- How did your experiences in college and graduate school prepare you for your current career?

- What was your favorite class you took during your education?

- What do you enjoy the most about working in 3D printing?

- Can you tell us about an exciting project you’ve worked on?

- What are some other real-life applications of 3D printing?

- Did anything surprise you about your role when you first started?

- What is the key to balancing your work life and personal life?

- Could you walk us through a typical day in your life?

- What skills would you say are essential for your job?

- Is there anything you wish you had known before you started working in 3D printing?

- How exactly does 3D printing work?

- How long does it take to build a 3D printing module?

- What would you say to a student interested in 3D printing or STEM in general?

- What books/resources would you recommend for learning more about 3D printing and robotics?

- What advancements in 3D printing do you hope to see in the future?

How did you first become interested in STEM?

As a kid, I had some guidance, but I wasn't following it. I just didn't know what I wanted to be when I grew up. I played the flute in band and thought, maybe this is the skill that I need to get a career. It wasn't until high school that I discovered the robotics team. My brother was on it, and he got to go to a robotics competition in Florida. I wanted to go to Florida, so I joined the team. On the team, I realized what STEM and engineering were and just fell in love.

(Credit: Dr. Amy Elliott)

How did your experiences in college and graduate school prepare you for your current career?

After high school, I was in college for 10 years getting a bachelor's and then a PhD. The reason I decided to get a PhD was because I worked really hard in my undergraduate studies and had done a lot of extracurriculars early on. We have a Baja SAE team here in the States as well as the NASA Moon Buggy (Lunar Roving Vehicle)—the extracurriculars where you spent time in the shop. I really liked that, and it allowed me to gain experience in the field. I worked so hard that I felt like I didn't get the student experience, so I wanted to stay in school for a little bit longer. I went to grad school thinking I would just get a Master's, but then ended up with a PhD, which was actually a really great decision.

What was your favorite class you took during your education?

I really enjoyed thermodynamics because it was all algebra-based. There was very little calculus, and I really enjoyed calculating enthalpies and doing that kind of thing. In grad school, I really liked the ceramics class, but my favorite class was the design of experiments class. We learned about the Taguchi method and orthogonal arrays, which is a really cool way to structure an experiment. You can do as few samples as possible but still understand what's going on in your process. That was my favorite class because it was so powerful.

Amy leading the world’s first 3D printing vending machine, DreamVendor (Credit: Virginia Tech)

What do you enjoy the most about working in 3D printing?

I really enjoy the discovery. There are moments when things are starting to click and concepts are starting to come together. When you've discovered something that could be significant or you've done an experiment, and the results are really interesting, you can say, “Look, this is really valuable information.” That's what I love the most—being able to find something new or useful when you get a patent. I've got a few patents now, and when those get licensed by a company, they will be using that technology. That’s my favorite aspect of the job, and it’s the best feeling in the world.

"I really enjoy the discovery. There are moments when things are starting to click and concepts are starting to come together."

Dr. Amy Elliott

Can you tell us about an exciting project you’ve worked on?

In general, we do a lot of work with materials and 3D printing just in terms of trying to figure out what the boundaries of their processes are. We look at what materials we can print and what ones we can't print.

One of the coolest materials we've printed is silicon carbide, which is a really high-temperature material that’s really hard to shape. Using our technology, we are able to shape it into a very complex geometry. Now we're working on making silicon carbide heat exchangers, which a few years ago would have been a bizarre thought. We aim to use these high-temperature heat exchangers to increase efficiency in power generation and any other processes where we have high temperatures in order to recover that waste heat. Since the vast majority of our wasted energy is in waste heat, things like high-temperature heat exchangers can save us a lot of energy. This may not be as attractive as some other 3D-printed things, but it's really important.

"Since the vast majority of our wasted energy is in waste heat, things like high-temperature heat exchangers can save us a lot of energy."

Dr. Amy Elliott

What are some other real-life applications of 3D printing?

There are so many applications of 3D printing. The obvious one is medical. All of our bodies are different, but when you use 3D printing, you can make a custom part that's shaped to match your body. A lot of the prosthetics nowadays like hip implants or knee replacements, especially in Europe, are 3D printed because not only can they size and shape them properly, but they can also put texture on the surface called a lattice or cellular structure, which is like a 3D chain link fence that your bone grows into. This application is unique because it can extend the lifetime of the implant, and it can only be done with 3D printing.

There are actually a lot of consumer products out there that involve 3D printing. For example, you can go to shapeways.com and order custom jewelry or figurines.

But, I think the greatest application for 3D printing is in the automotive industry. Soon we will see automotive companies start embracing 3D printing for production and not just prototyping or tooling.

Did anything surprise you about your role when you first started?

I am surprised about how much administrative work I have, which I think goes with pretty much any job. I felt like I would be spending more time in the lab, but my work ends up being more proposals and the logistics around experiments. There are things that you have to do as a scientist that are not really science but are part of running a lab, and that's what kind of surprised me. I think every job has those tasks that come with it that nobody likes. There's no perfect job out there.

Amy in the Salt Flats of Utah as part of Eva Hakansson's land-speed racing team (Credit: Dr. Amy Elliott)

What is the key to balancing your work life and personal life?

Read all of the productivity books, learn all of the tips, learn how to be efficient, and learn how to prioritize. There's a matrix where you can decide if things are important and urgent, unimportant and urgent, or unimportant and non urgent, etc. You can categorize your tasks that way.

Honestly, you have to give up on being a perfectionist. In certain jobs, especially something that's so fast-paced like research, you have to decide if this much time and effort is required for a task or not. There are a lot of different things you have to learn, but it's all part of being a productive person and getting things done. It sounds miserable, but it's actually very fruitful if you learn your system.

Could you walk us through a typical day in your life?

I get up around 6:00 AM and get ready. I then get my two sons ready for the day. I take my 11-month-old son to daycare, while my two-year-old stays home with my mom. My husband's in school right now, so he leaves when he needs to. I get to work, and I usually do a lot of email correspondence. As I said there are a lot of logistics around experiments and proposals that we're writing and a lot of people inquiring about using our technology. I’m the group leader, so there are some things that I have to do for that. Usually, I have several meetings throughout the day. I do try to get in the lab. I don't get as much time in there as I want to, but that would be the other thing that I do in the day.

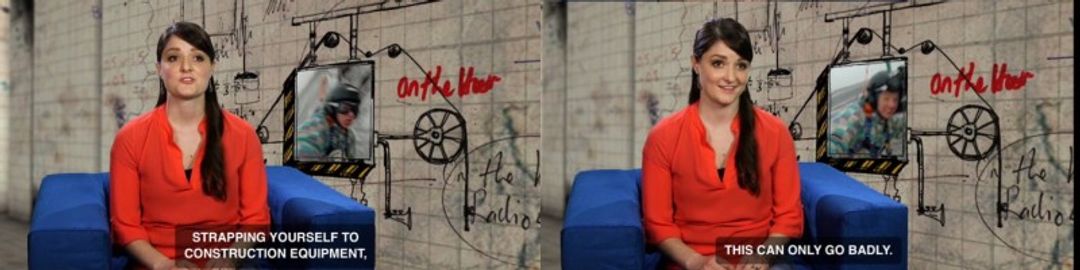

Amy serving as an on-camera science personality on Outrageous Acts of Science (Credit: Science Channel)

What skills would you say are essential for your job?

Organization, quick decision-making, being able to connect the dots between all the things that are going on, and being able to delegate and communicate are essential. On top of being skilled in your trade and understanding your science, you should also have some administrative skills.

Is there anything you wish you had known before you started working in 3D printing?

I wish I had taken more materials science courses because all of my education is in mechanical engineering, which is great and very useful, but there's so much materials science in 3D printing. I've learned a lot, and I feel like I've done a pretty good job catching up, but it probably would have benefited me to have a few more materials science courses.

Amy featured on The Big Brain Theory (Credit: Discovery Channel)

How exactly does 3D printing work?

3D printing works by building objects layer by layer, and there are a lot of ways to do that. The most common way is to extrude molten plastic through a nozzle and then draw the shape of the layer. It's kind of like a hot glue gun where you draw a square with the hot glue gun, let it cool, and draw another square on the top. If you keep drawing squares, you'll eventually have a three-dimensional cube.

The technology that I work with prints metals, so instead of using a nozzle and liquid plastic, we use metal powder and an inkjet printhead. We spread metal powder into a layer and use an inkjet printhead to glue that layer into the shape that we want over and over again. We get a box of powder with glue arranged in the shape of our part, so we dig it out and go center it in a furnace, just like a piece of pottery, to get a fully dense metal part.

Those are just two of the different ways you can 3D print things, but there are actually seven different technology types of 3D printing. In addition to that, there are a lot of different shape factors in terms of how the machines are built and how they're configured.

How long does it take to build a 3D printing module?

We have lots of different types of projects. Sometimes we do build 3D printers, so we have our own custom hardware. That can take anywhere from a few months to maybe a year to get a full system going. We also do a lot of prints ourselves. Prints can range from just a few hours to a few days. The longest print we did was about a month long. We try not to print things that long because who knows what can go wrong during that time. The power could go out, the gases could go out; it’s very risky.

Amy's statue in the AAAS Smithsonian exhibit (Credit: Amy Elliott)

What would you say to a student interested in 3D printing or STEM in general?

We really need tradespeople who know how to weld and who know machines and electrical. There's just not enough of those people, so that’s a really great career option if you'd like to be more hands-on.

If you're interested in STEM, I would say explore different options and look at different topics. If you don't find the right one off the bat, that doesn't mean you're not meant for STEM. Just keep looking; almost anything you are interested in there's a STEM field behind.

What books/resources would you recommend for learning more about 3D printing and robotics?

There are a lot of technical books about 3D printing that you could get, but one of my favorite books that's for a layperson about 3D printing is called Fabricated by Hod Lipson. It's a really forward-thinking book about what 3D printing could be in the future. In terms of productivity books, I don't have a single one, but I feel like all of them have good information. I use the app Blinkist where you can get a quick synopsis of the different self-help books. That’s how I can get through a lot of books in a short time.

What advancements in 3D printing do you hope to see in the future?

We still have a lot of work in the fields. One of the things that we're working on here is the digital factory, which is basically having so much information about what we're printing and what we're doing that we can qualify parts as they're being made and track parts in their life-use to see how they're doing and improve upon that with that information.

Personally, I'm excited about multi-materials. We can do a lot of 3D printing with single materials, and that's great. But now, I think we have the opportunity to print with multiple materials and really tailor material properties according to location. That's going to open up a whole new world of efficient devices for power generation, transportation, you name it.

Learn More:

- FIRST Robotics Competition: https://www.firstinspires.org/robotics/frc

- Shapeways custom 3D printing service: https://www.shapeways.com

- Fabricated: The New World of 3D Printing by Hod Lipson

- Blinkist (book summarization app)